Layer Chicken Cage

Automatic Poultry Chicken Farm Layer Chicken Cage for Sale

Layer cages are chicken cages specially designed for laying hens. After hatching out from the egg incubators, the baby chick is put into chick cage and then transferred to layer cage normally at 18 to 20 weeks, and will be raised there until 72 weeks. Like broiler cages and chick cages, YESON layer cages also provide laying hens with a healthy, clean and comfortable environment. The main differences between different chicken cages are the design and structure. The scientific design and strong built net wire enable laying hens to perform their highest production efficiency.

The intensively designed layer cage system, with advanced automatic feeding, drinking water, manure cleaning, egg collection, and air quality control systems, fully saves energy consumption and improves labor productivity. Focusing on the production needs of modern laying hens, YESON can provide the design and manufacture of A-type chicken cages, H-type chicken cage equipment, and layer cage house breeding systems according to the planning and service life of the customer chicken farm.

Layer Chicken Cage Details

Product: A type layer cage, H type layer cage

Application: laying hens of poultry farm

Material: Hot galvanized, cold galvanized (according to customers’ requirement)

Tiers: A-Type(3-4 Tiers) , H-Type(3-6 Tiers or duplex multilayer 4+4 and 3+3+3 Tiers)

Lifespan: Last 20-30 years

Sales volume: Customers cover 80+ countries

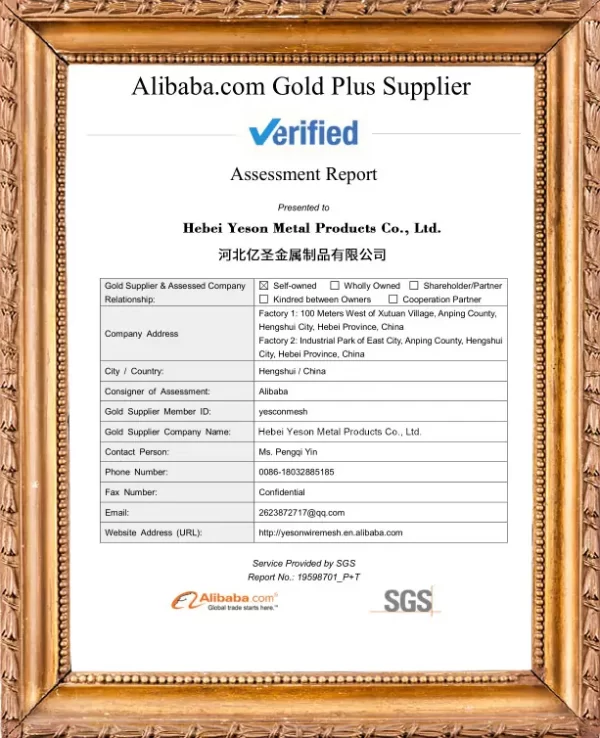

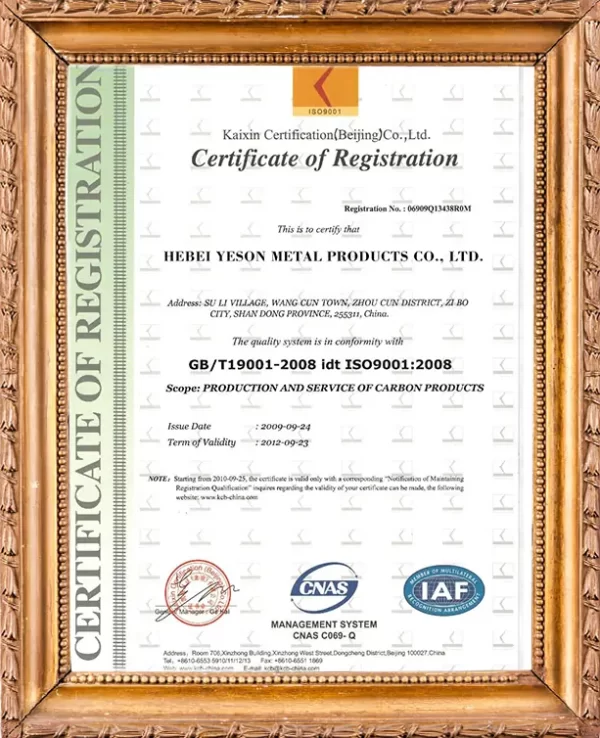

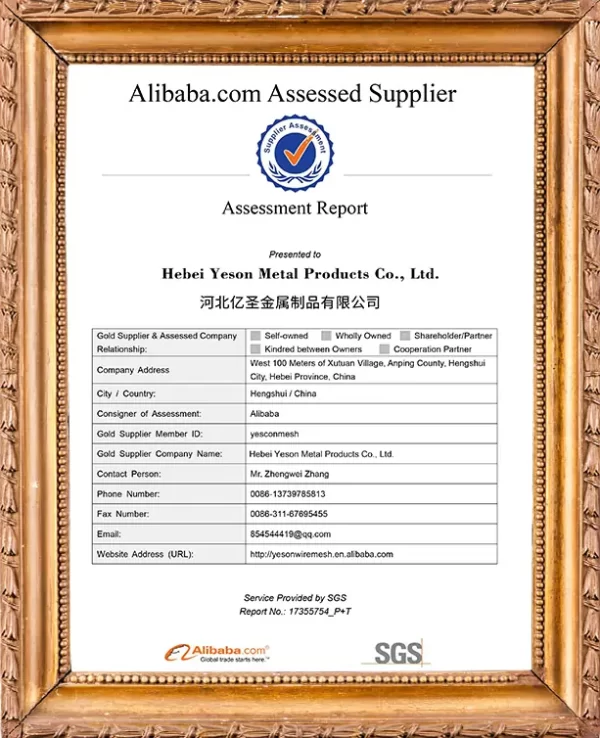

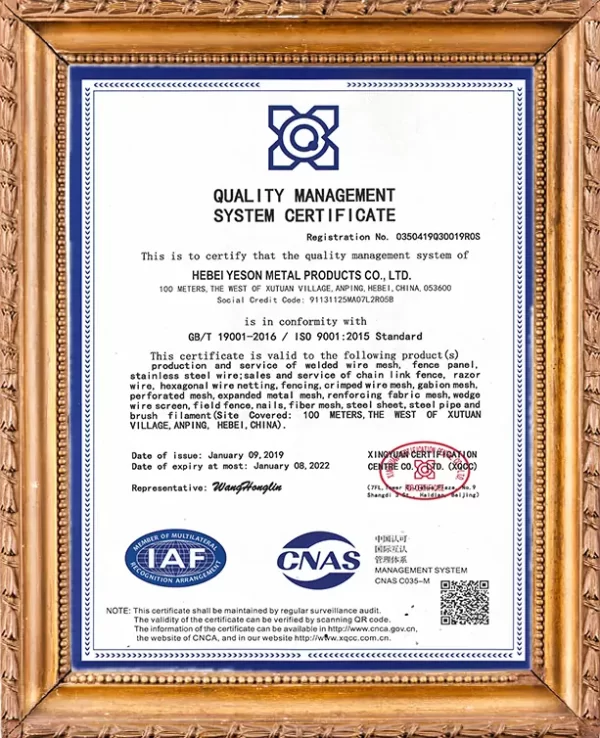

Certificate: ISO9001, CE, SGS, SONCAP

Size(mm): A-Type: 3-tiers 2150×1870×1550, 4-tiers 2150×2050×2065

H-Type: 3-tiers 1800×1200×2140, 4-tiers 1800×1200×2790

Hot sale Layer Chicken Cages Type

Manual A type layer chicken cages

❖ Features: simple structure, convenient operation and maintenance, low input cost and quick return. ❖ Price: Manual A type layer chicken cage is cheaper than H type layer cage. ❖ Poultry equipment: only A type chicken cages, or add scraper cleaner and a semi automatic chicken feeding trolley. ❖ Application: poultry farms with lower than 5,000 chickens.

Fully automatic A type layer cages

❖ Features: Fully automatic, high productivity, Easy to manage ❖ Poultry equipment: includes layer cage system, automatic feeding, drinking water, manure cleaning, egg collection, and environmental control system. ❖ Price: prices fluctuate based on poultry automation equipment required ❖ Application: suitable for poultry farms with 10,000 chickens and above.

Fully automatic H type layer cages

❖ Features: high automation and high density, save land, save labor. Compared with A type layer cages, H type layer cage equipment has a higher stocking density and has a higher cost effectiveness in the long run. ❖ Poultry equipment: includes layer cage system, automatic feeding, drinking water, manure cleaning, egg collection, and environmental control system. ❖ Price: The price is slightly higher than A Type layer cages, but we can offer you a favorable factory price. ❖ Application: suitable for poultry farms with 30,000 chickens and above.

Design diagram of Layer Chicken Cage

Reasonable design program Easy to deal with farming problems

The company designs and plans a reasonable equipment layout according to the topography of the customer’s breeding area, which increases the air quality, enables the chickens and ducks to have a growing environment, and makes it easy for the workers to operate and manage the equipment.

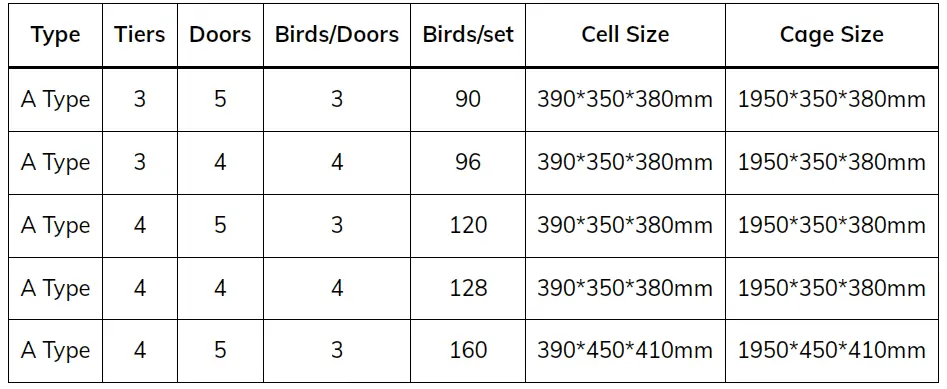

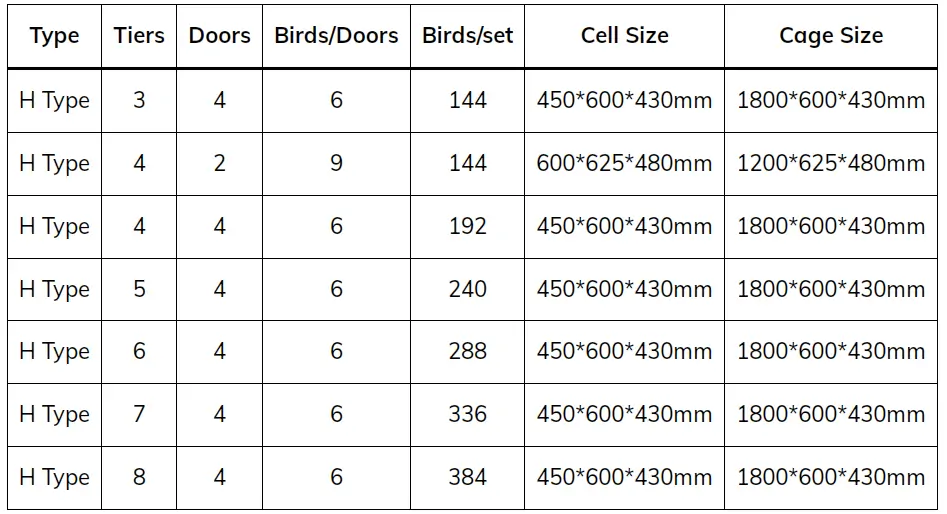

Layer chicken Cages Specification

Advantages Of Our Layer Chicken Cages

Q235 High Quality Steel Material

275g/m² hot-dip galvanized steel, smooth surface, not easy to break eggs.

2.15mm U shaped Steel Frame

Chicken cages can withstand high weight without deforming

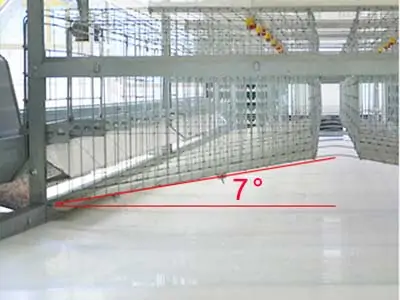

Bottom Mesh with 7 ° Slope

Proper slope allows eggs to slide into the egg tray, but not to the floor

High Tenacity Polypropylene Egg Belt

The polypropylene material is resistant to bacteria and fungi to prevent contamination of eggs.

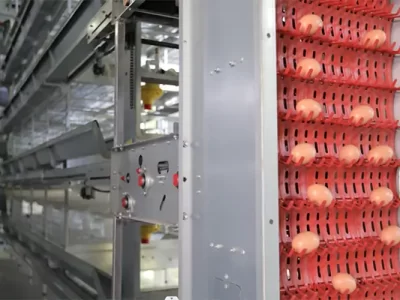

Automatic Egg Collection Equipment

Egg collection efficiency is high, collecting 3000-6000 eggs per hour

Egg Filter System

Can filter soft and broken eggs, leaving good eggs

Advantages of Automation System Accessories

Poultry feeding system

The poultry feeding system include feed silo, automatic ladder type feeding system, feed troughs and so on.

Poultry drinking system

The nipple drinking water system is useful, and the nipple drinker core is made of high-quality stainless steel. The water cup is also provided to ensure the chicken dung is dry.

Egg collection system

Adopt the conveyor belts make the eggs safely and steadily sent to the head of the chicken shed. Then sent to the other egg processing equipment to clean and pack.

Poultry manure removal system

Each layer is transported by the longitudinal conveyor belt to the tail end of the chicken excrement. At the same time, the chicken coop is transported horizontally and is transported diagonally to a dedicated transport vehicle.

Cage mesh with galvanized steel

YESON layer chicken cage wire with galvanized steel is anti-corrosive, which prolongs the service life of the laying hens cages and avoids the disease occurrence.

More Than Just a Layer Chicken Cage Manufacturer

High Quality Equipment

- All poultry battery cage has high quality, with hot-dipped galvanized steel Q235 as raw material!

- Our chicken farming equipment poultry battery cage are durable which means they last longer.

- We can provide a complete set of equipment for your chicken farm and provide corresponding solutions.

Strict Quality Control

- Our professionals will carry out strict quality inspection on the equipment before shipping it to customers.

- Quality battery cage system with CE and ISO certification. We implement quality monitoring throughout the whole process!

Best Service and Rich Experience

- YESON poultry battery cage manufacture offers one-stop service from designing to installing battery cage system, customers can avoid purchase risk to a great extent due to our pre-sale, on-sale, after-sale services!

- Our battery cage factory has more than 30 years of battery cage system export experience! Our battery cage system export to more than 80 countries!

FAQ

Can I come to China for Factory inspection?

Of course, you are welcome to visit our factory or offices in different cities anytime. Now we also support ZOOM or WeChat for online factory inspection.

Can I have a sample to check first?

Yes, we do offer raw materials samples or small trail sample order for you to check. Just tell our specialists of the details and they’ll help you about it.

Are you trading company or manufacture?

We are factory – nearly 30 years of experience for production, and morethan 25 years of exporting experience.

How long is your delivery time?

Generally it is 7 days if the goods are in stock. And 30-40 days if OEMit is according to the quantity.

How can l know my order progress?

Production and packages photos will be supplied and confirmed with you before loading.

What is the most important feature of your products?

Since we have an independent design team(10+ members), we accept all forms of customization, you just give us ideas or even just a word, and we can manufacture your ideal product for your market.