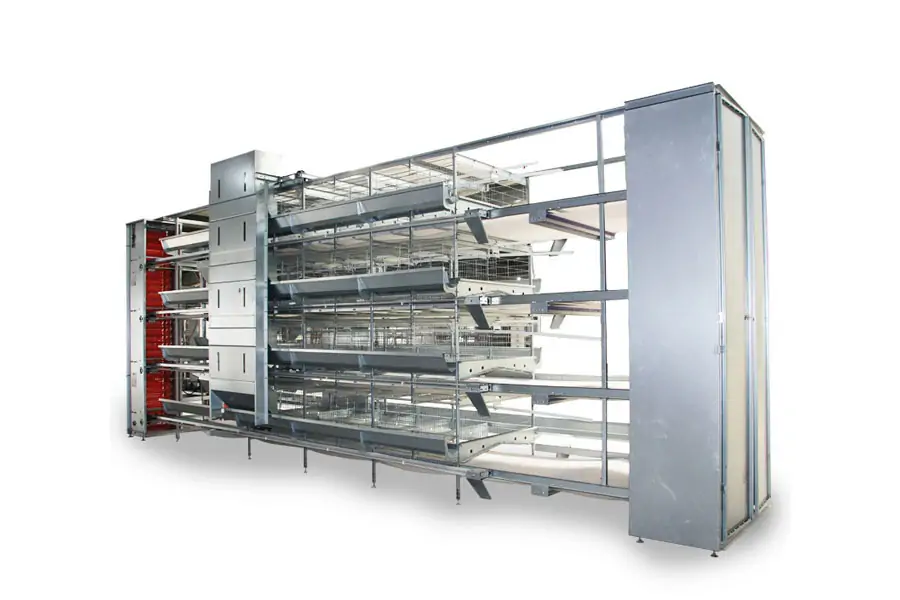

H Type Layer Cage

H Type Automatic Stacked Layer Cage System for Poultry Farm

The design of the H type layer cage is like a building. The cages layer by layer is stacked together to form a chicken cage system. H type layer cages have gradually developed and become popular in recent years. Due to the increasing shortage of land resources, there is less and less land that can be used for laying hens. Therefore, more and more customers increase the density of laying hens, which greatly saves land. Compared with the A-type cage system, the H-type chicken cage system is more intensive. Generally, it can be stacked with 3-8 layers. Some chicken farms can even use as many as 8-10 layers of H-type chicken cages. H-type layer chicken cages are suitable for large-scale chicken farms with a higher degree of mechanization. The breeding capacity of a chicken house can easily reach 100,000.

275g high zinc plate frame, hot-dip galvanized welding mesh cage, bending galvanized plate food trough, strong material and resistant to corrosion, can be used for more than 20 years; Multi-layer, fully assembled structure, high precision of equipment production, solid installation, and convenient maintenance in the later period; Equipped with automated control system, easy to operate, reduce labor costs, chickens are less likely to get sick, and the yield is 2- 4 times higher than traditional farming; Different styles, can be customized according to needs.

H Type Battery Cage Details

Breeding volume : More than 30,000 birds

Tier : 3 tiers , 4 tiers , 5 tiers , 6 tiers , 7 tiers , 8 tiers

Capacity : 120 birds , 144 birds , 192 birds , 240 birds

Size: 1800*600*430mm, 1200*625*480mm

Material : Hot dipped galvanized, Q235

Applicable Industries: Poultry Farms / Chicken Farms

Use: Layers , broilers , baby chicks

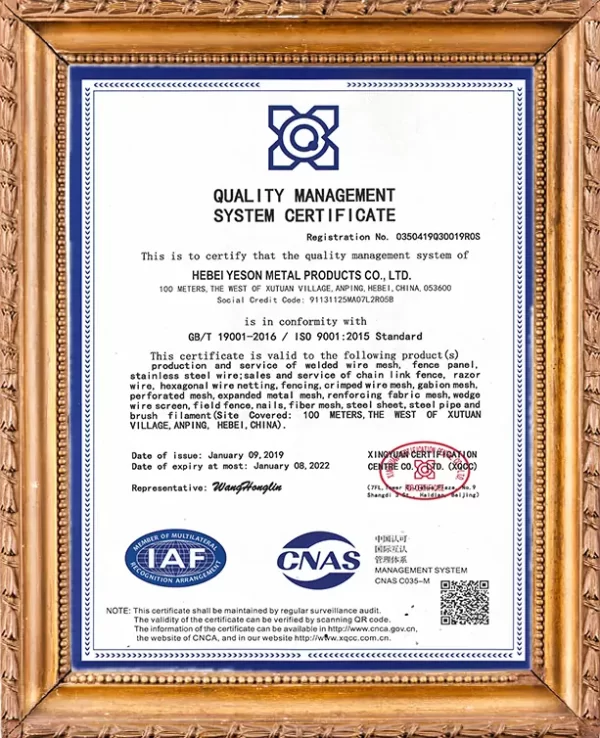

Certification: ISO 9001, ISO 14001, SONCAP, CE.

Service life : 15-20 years

Service : Customized

Design diagram of H type chicken cage

Reasonable design program Easy to deal with farming problems

The company designs and plans a reasonable equipment layout according to the topography of the customer’s breeding area, which increases the air quality, enables the chickens and ducks to have a growing environment, and makes it easy for the workers to operate and manage the equipment.

H Type Poultry Battery Cage Specification

H-type automatic chicken battery cage system comes from its H-frame structure, it is a high-density poultry breeding system. It can save labor costs, land, and reduce construction investment and management costs. It is an ideal choice for intensive large-scale poultry farms. The high-quality hot-dip galvanized material features excellent corrosion-resistant, and the cage service life can be up to 20 years.

| H Type Poultry Battery Cage Specification | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cage size | Nos. of Door/cage | Nos. of Chicken/door | Nos. of Floor | Capacity of one set of cage | Area per head (sqcm) | Length of the cage with frame | Width of installed cage with feeding machine | Height of installed cage with feeding machine |

| 1950*450*410 | 5 | 4 | 4 | 160 | 438.75 | 2000 | 1760 | 3035 |

| 1800*500*410 | 4 | 5 | 4 | 160 | 450 | 1850 | 1860 | 3035 |

| 1800*600*430 | 4 | 6 | 4 | 192 | 450 | 1850 | 2010 | 3210 |

Product Features

❖ The chicken battery cage system adopts hot-dip galvanizing process, which provides good corrosion resistance in humid environment.

❖ Automatic feeding, drinking, manure cleaning, egg collecting and environment control, can help to improve working efficiency and save labor cost.

❖ Have sufficient feed, water position and healthy uniformity are better chicken, chicken limited to the minimum amount of exercise, energy consumption, save feed.

❖ High-density raising, saves land and investment. The chicken cage allows you easily observing birds, clustering or choosing the weak

❖ Automatic control of ventilation and temperature can meet the requirement of the birds.

❖ Easy to manage, improve production efficiency

❖ Save space and maximize land utilization

Get a Free Quote!

Don't wait, contact our team for a personalized quote and fast delivery to keep your business running smoothly!

Advantage Of H Type Fully Automatic Chicken Equipment

2 to 5 Times Raising Quantity

❖ 2 to 5 times higher capacity compared to A Type. ❖ Suggested chicken capacity/house> 30000 birds. ❖ Ideally suited for large-scale chicken farms.

Optimal Raising Results

❖ Laying rates min 96%. ❖ Eggs Damaging Rate does not exceed 0. 3%. ❖ 20 years service life.

Only one person manages

❖ Automatic feeding, drinking, and egg collecting. ❖ Automatic remove manure ❖ Intelligent control environment ❖ Smart warning of environmental control problems.

Upgraded to smart farm

❖ Integrate all data of the farm. ❖ Smart control the whole farm. ❖ Inspect the chicken house at any time. ❖ A timely reminder of environmental changes.

Advantage of Accessories

Cage Mesh Material

❖ The frame and cage mesh are made of Q235 steel, the European equivalent material is S235 steel. ❖ The battery cage surface is hot-dip galvanized 275g/m2 or Galfan wire, lifespan up to 15-30 years. ❖ The smooth surface does not hurt the birds. Egg broken rate is less than 0.5 per thousand. Solid structure, not easy to deform.

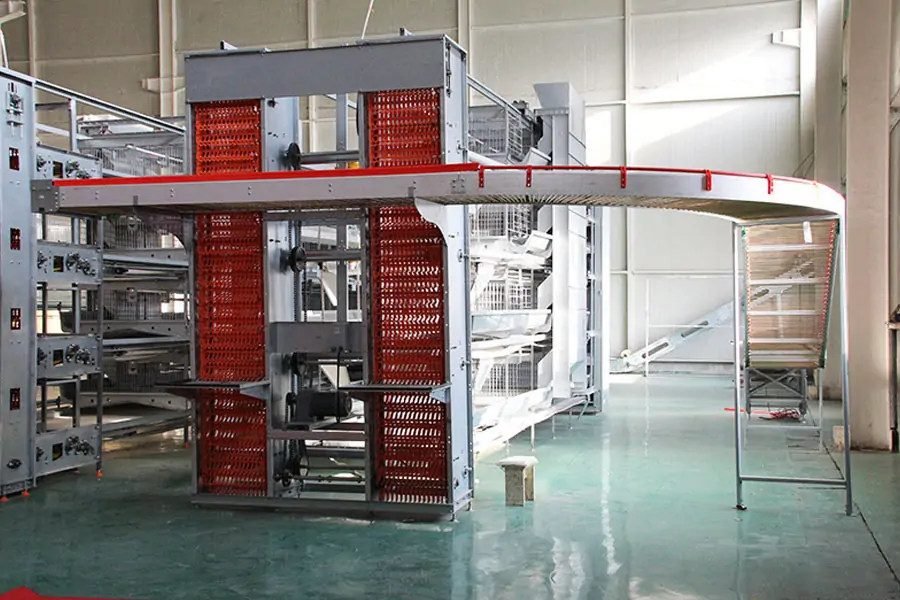

Automatic Egg Collection System

Belt conveyor is adopted, the process is stable, gentle, low egg breakage rate, the conveyor belt uses environmentally friendly materials, not easy be polluted; the egg diversion and secondary removal mechanism can remove soft eggs, broken eggs, and divert eggs to the designated position of the egg collection machine; the egg machine has a collection capacity of up to 60,000 eggs/hour, greatly improving the working capacity and reducing labor costs.

Automatic Feeding System

Saddle-type feeder, stable transmission, uniform feeding, reduce manual feeding spillage, save feed. 1. Feed Silo: ❖ Capacity: 5-30 Tons ❖ Material: hot-dipped galvanized, Zinc ❖ coated: 275g/m² ❖ Feed lifting and weighing device can be installed ❖ Delivery Pipe Diameter: 90mm 2. Automatic Feeder Equipment ❖ Feed hopper: 2 hoppers/tier, ❖ Capacity per hopper: 60 kg. ❖ Speed: Adjustable

Automatic Drinking System

Automatic water replenishment design, PVC water pipes, nipple-style drinkers, clean and sanitary, reduce water waste.

Automatic Manure Cleaning System

Chicken manure is conveyed to the cross-clearing belt through the longitudinal clearing belt, and then to the transport vehicle by the clearing conveyor belt. The whole process of manure removal keeps the chicken manure from touching the ground, reducing environmental pollution and improving the utilization rate of chicken manure.

Intelligent Environmental Control System

The poultry ventilation systems monitors the environmental data of the chicken house constantly based on temperature and humidity sensor-data. It controls the cooling fans, cooling pads and the clearstory automatically by a microcomputer integrated system.

More Than Just a H type layer cage Manufacturer

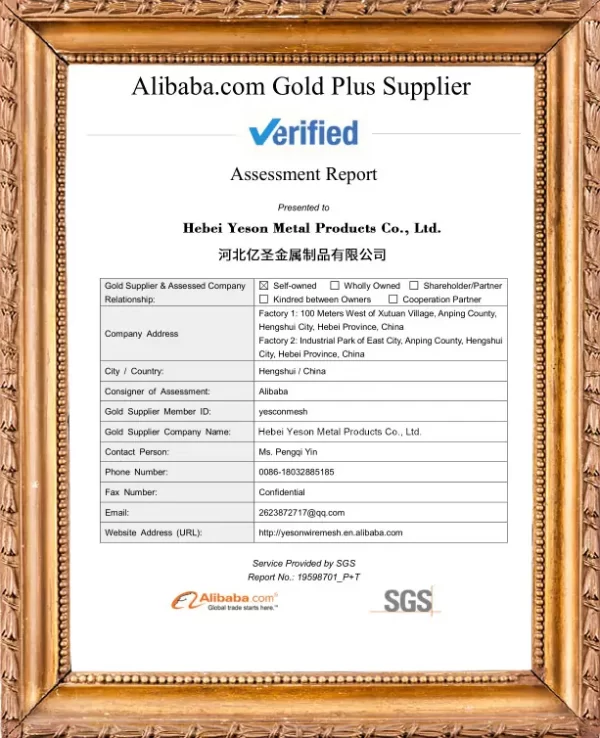

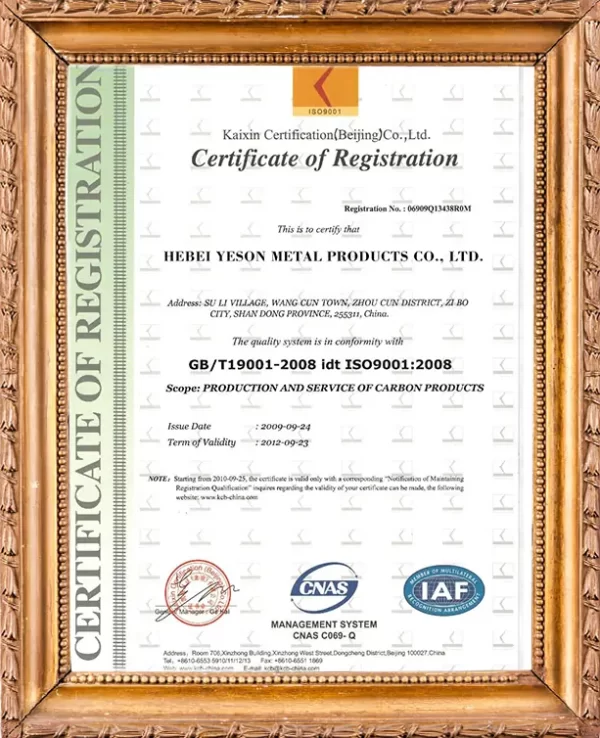

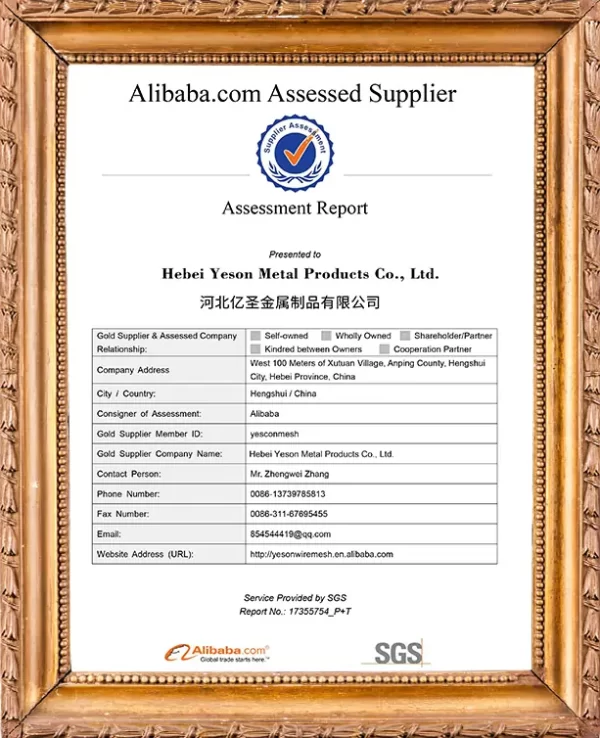

ISO, TUV, BV Approved

YESON is certified by ISO, TUV, and BV, ensuring our products meet the highest international standards. Trust us for reliable cattle fence backed by global certifications.

Huge Stock, Fast Delivery

With large inventory, we can fulfill orders quickly, minimizing your downtime. Our streamlined logistics ensure fast and efficient delivery around the world.

100% Tested

Each product is rigorously tested to guarantee performance and reliability. We ensure zero defects, so you can trust our products for your project.

Small MOQ

We accommodate orders with small minimum order quantities, making it easy for businesses of all sizes to work with us. Start with a small batch and scale up as needed.

Free Samples

Request a free sample to evaluate our product quality and perfection with your project. We are sure you will see why YESON is a manufacturer you can trust.

Customizable Solutions

From material selection to size, shape, and branding, we offer tailored solutions to meet your exact specifications. Collaborate with us to create the perfect products for you.

FAQ

Can I come to China for Factory inspection?

Of course, you are welcome to visit our factory or offices in different cities anytime. Now we also support ZOOM or WeChat for online factory inspection.

Can I have a sample to check first?

Yes, we do offer raw materials samples or small trail sample order for you to check. Just tell our specialists of the details and they’ll help you about it.

Are you trading company or manufacture?

We are factory – nearly 30 years of experience for production, and morethan 25 years of exporting experience.

How long is your delivery time?

Generally it is 7 days if the goods are in stock. And 30-40 days if OEMit is according to the quantity.

How can l know my order progress?

Production and packages photos will be supplied and confirmed with you before loading.

What is the most important feature of your products?

Since we have an independent design team(10+ members), we accept all forms of customization, you just give us ideas or even just a word, and we can manufacture your ideal product for your market.