Broilerkäfig

Automatic Harvesting Broiler Chicken Cage

Broiler chicken cages are mainly used in commercial poultry broiler farming. The utility model has a reasonable design, which can reduce the fatigue degree of the chicken and enable the broiler to grow in a comfortable environment. In addition, the broiler cage system can improve the utilization rate of the chicken house, improve the efficiency of poultry breeding, and finally bring more profits to poultry farmers.

Automated poultry farming equipment broiler chicken cage is of great significance in the poultry farm. It can realize automatic feeding, drinking water, defecation, environmental control, etc. It can manage poultry more efficiently and increase poultry production. We provide H-type broiler cage and broiler floor raising system, which can meet the needs of different farmers, so that you can raise more poultry on the same land.

Broiler Cage System

Capacity: 102,120 bird one set

Größe: 1050mm*800mm*420mm

Lebensdauer: 15-20 Years

Material: International Q235 steel.

Anti-corrosion treatment process: Hot-dip galvanized

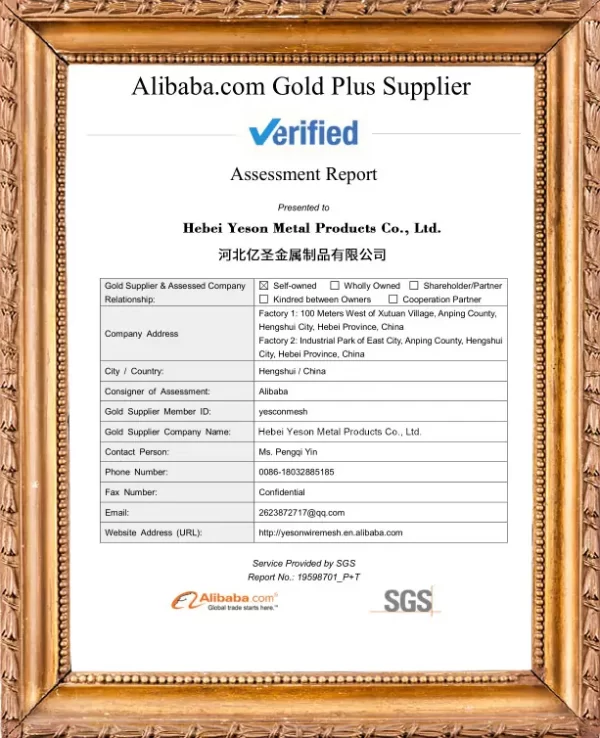

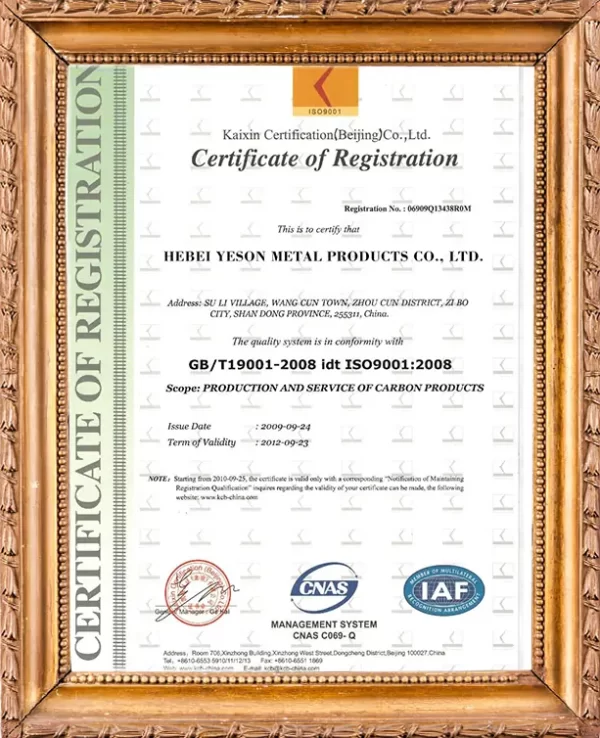

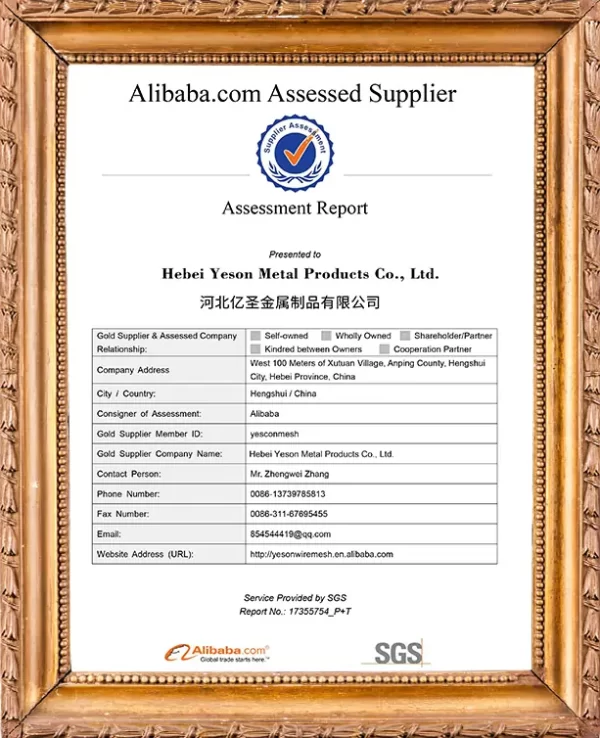

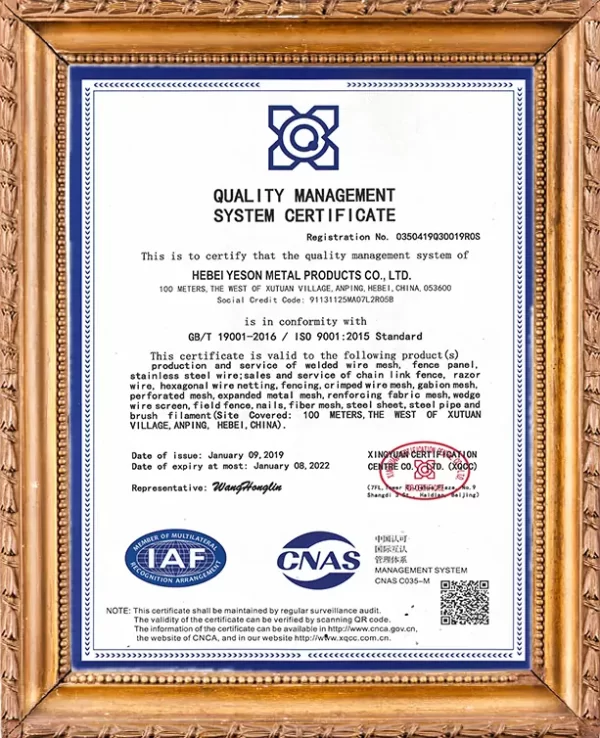

Zertifikat: ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC

Production Lead Time: Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container.

Supply Ability: 10000 Set/Month

Packing Method: Normal export packing. 20ft / 40ft container.

Payment Method: T/T, L/C at sight

Trading Method: EXW, FOB, CFR, CIF

Save labor

Less harvesting labor

Save time

Bird-harvesting>6000 birds/hr

Save Feed

Feed-to-meat Ratio 1.4:1

Long Lifespan

15-20 years

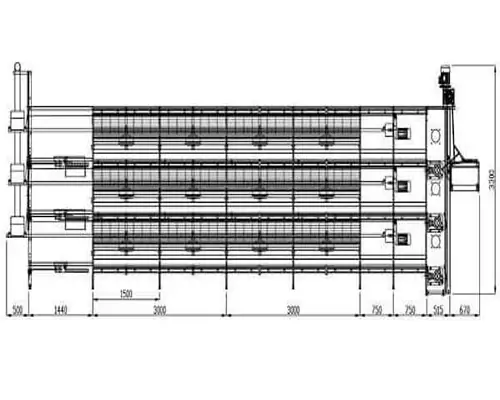

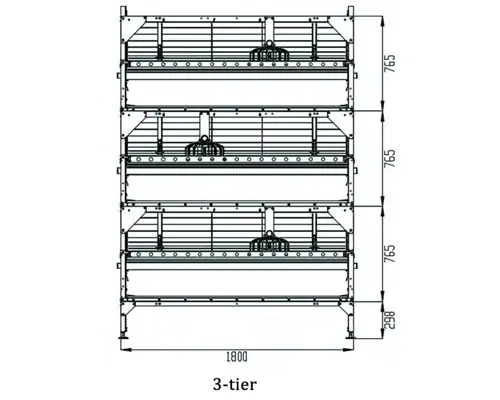

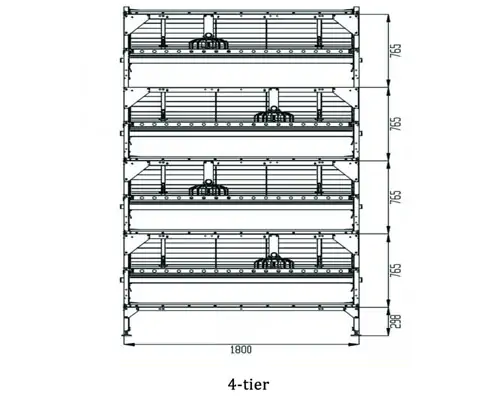

Automatic Broiler Chicken Cage Drawing

Reasonable design program Easy to deal with farming problems

The company designs and plans a reasonable equipment layout according to the topography of the customer’s breeding area, which increases the air quality, enables the chickens and ducks to have a growing environment, and makes it easy for the workers to operate and manage the equipment.

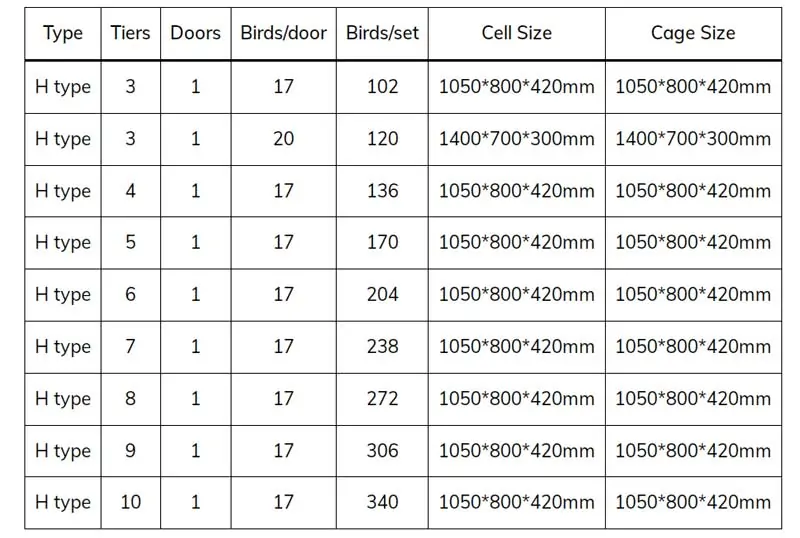

Broiler Chicken Cages Specification

Automatic Broiler Chicken Cage Product Details

Cage and Frame

❖ Surface treatment: 275gsm zinc coating

Feed Silo

❖ 10T to 30T feed capacity is available ❖ Hot galvanized: 275g/㎡

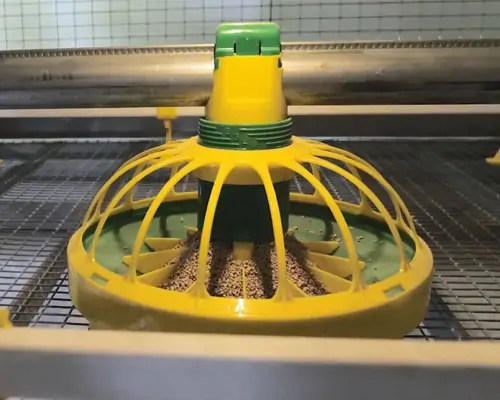

Pan Feeding System

❖ Feed sensor: IFM® ❖ Feed pipe: hot galvanized

Drinking System

❖ Two different water supply lines are placed in each cage with 8 to 12. ❖ 360° water supply of the nipples.

Manure Cleaning System

❖ PP belt, 1.2mm thickness

Automatic Ventilation

❖ Ideal environment for chickens with constant temperature and humidity

Automatic Lighting

❖ The lighting system is inside the cage, it is bright, non-glare, and flicker-free. Chicks can find the feed and water easily. ❖ Suitable light intensity promotes growth.

Steel Structure House

❖ Customized prefab steel structure chicken house based on the local environment

Advantages of Automation System Accessories

1. Made of hot-dip galvanized wire mesh, hot-dip galvanized steel plate and steel pipe, the material is strong and anti-rust, and can be used for more than 15 years.

2. The whole equipment is exquisitely designed, with a unique cage frame design, stable and durable.

3. Equipped with automated control system, easy to operate, reduce labor costs, chickens are less likely to get sick, and the yield is 2- 4 times higher than traditional farming.

Feeding system

saddle-type feeder, stable transmission, uniform feeding, reduce manual feeding spillage, save feed.

Hanging cup drinker

High-quality water drinking cups, pressure valves and 360-degree drinking nipples can effectively prevent the water leakage and drinking system adopt the closed piping system, which can minimize the water pollution.

Manure removal system

The crawler manure removal system is adopted, the manure removal belt is made of PE material, which has good toughness, corrosion resistance, anti-aging, and easy to clean.

Manure removal system

Chicken manure is conveyed to the cross-clearing belt through the longitudinal clearing belt, and then to the transport vehicle by the clearing conveyor belt. The whole process of manure removal keeps the chicken manure from touching the ground, reducing environmental pollution and improving the utilization rate of chicken manure.

Intelligent environmental control system

High-quality fans and wet curtains, ensuring a healthy growth environment for the chicken coop.

More Than Just a Broiler Cage Manufacturer

High Quality Equipment

- All poultry battery cage has high quality, with hot-dipped galvanized steel Q235 as raw material!

- Our chicken farming equipment poultry battery cage are durable which means they last longer.

- We can provide a complete set of equipment for your chicken farm and provide corresponding solutions.

Strict Quality Control

- Our professionals will carry out strict quality inspection on the equipment before shipping it to customers.

- Quality battery cage system with CE and ISO certification. We implement quality monitoring throughout the whole process!

Best Service and Rich Experience

- YESON poultry battery cage manufacture offers one-stop service from designing to installing battery cage system, customers can avoid purchase risk to a great extent due to our pre-sale, on-sale, after-sale services!

- Our battery cage factory has more than 30 years of battery cage system export experience! Our battery cage system export to more than 80 countries!

Häufig gestellte Fragen

Kann ich zur Fabrikinspektion nach China kommen?

Selbstverständlich können Sie unsere Fabrik oder unsere Büros in verschiedenen Städten jederzeit besuchen. Jetzt unterstützen wir auch ZOOM oder WeChat für die Online-Fabrikinspektion.

Kann ich vorab ein Muster zur Überprüfung erhalten?

Ja, wir bieten Ihnen Rohstoffproben oder kleine Probebestellungen zur Prüfung an. Teilen Sie unseren Spezialisten einfach die Details mit, und sie helfen Ihnen gerne weiter.

Sind Sie ein Handelsunternehmen oder ein Hersteller?

Wir sind eine Fabrik mit fast 30 Jahren Erfahrung in der Produktion und mehr als 25 Jahren Erfahrung im Export.

Wie lange ist Ihre Lieferzeit?

Im Allgemeinen beträgt die Lieferzeit 7 Tage, wenn die Ware auf Lager ist. Bei OEM-Ware beträgt sie 30–40 Tage, abhängig von der Menge.

Wie kann ich den Fortschritt meiner Bestellung verfolgen?

Produktions- und Verpackungsfotos werden bereitgestellt und vor dem Laden mit Ihnen bestätigt.

Was ist das wichtigste Merkmal Ihrer Produkte?

Da wir über ein unabhängiges Designteam (mehr als 10 Mitglieder) verfügen, akzeptieren wir alle Formen der individuellen Anpassung. Sie geben uns einfach Ideen oder auch nur ein Wort, und wir können Ihr ideales Produkt für Ihren Markt herstellen.